Big machines do hard work in farms, mines, and building sites. These powerful machines lift, push, and carry giant loads. But what gives them their strength? Hydraulic cylinders! These strong parts help machines move heavy things easily. Without them, machines like diggers, bulldozers, and cranes would struggle to do their jobs.

Hydraulic cylinders squeeze big power into small spaces. That’s why so many industries need them. Knowing how they work helps people pick the best machines for their jobs.

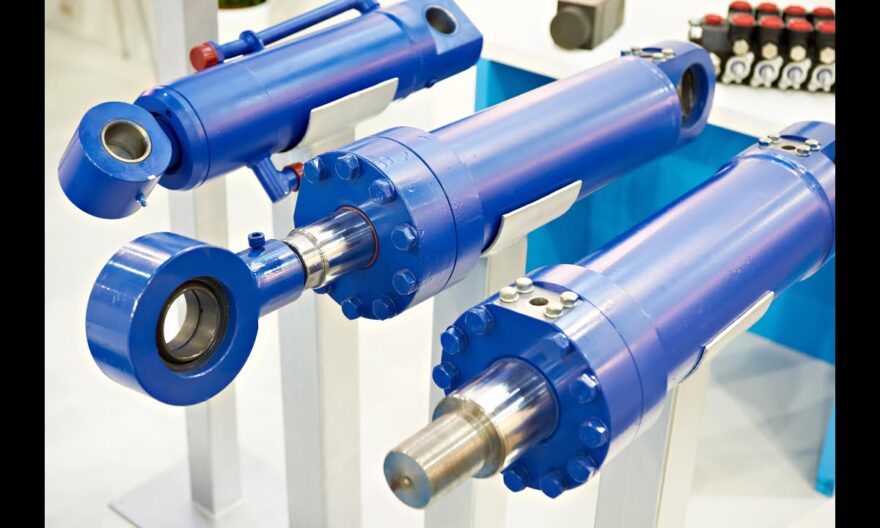

What Are Hydraulic Cylinders?

Hydraulic cylinders help machines move by turning liquid power into force. Special oil rushes through tubes, pushing parts to lift, pull, or push. This makes tough work easier. Many industries use hydraulic cylinders to power important machines.

Parts of a Hydraulic Cylinder

A hydraulic cylinder has many parts that work together:

- Cylinder Barrel – Holds the piston and oil inside.

- Piston and Piston Rod – Slide back and forth to create power.

- Seals – Block leaks and keep pressure strong.

- End Caps – Hold everything tightly together.

- Hydraulic Fluid – Moves through the system to create power.

- Ports – Let oil flow in and out to control movement.

Each part helps the machine work smoothly and safely.

How Hydraulic Cylinders Help Heavy Machines

Hydraulic cylinders make heavy machines stronger, steadier, and safer. Here’s how:

1. Lifting Mighty Loads

Cranes and forklifts need muscle to lift things high. Hydraulic cylinders push with great force, raising and lowering big loads.

2. Keeping Machines Steady

Machines that work on rough ground need balance. Hydraulic cylinders adjust weight and support to stop them from tipping over.

3. Speeding Up Work

Hydraulic cylinders help machines move at the right speed. Bulldozers push dirt at perfect angles. Dump trucks tip back smoothly. Machines work faster and better!

4. Handling Big Pressure

Machines in farms, mines, and building sites face rough conditions. Hydraulic cylinders handle strong forces without breaking. They help with drilling, crushing, and lifting.

5. Making Work Safer

Hydraulic cylinders move smoothly, stopping sudden jerks that could cause accidents. They also lock loads in place so nothing slips.

Why Hydraulic Cylinders Are Amazing

1. Mighty Strength

Hydraulic cylinders create huge power in a small space. They help machines do heavy lifting without taking up much room.

2. Built to Last

Hydraulic cylinders fight off dirt, pressure, and wear. With good care, they work for many years and save money.

3. Total Control

Operators can move machines with great accuracy. Hydraulic cylinders help machines stop, lift, or turn at just the right time.

4. Save Energy

Hydraulic cylinders use less power than other systems. They provide steady force without wasting energy.

5. Easy to Take Care Of

Simple checks and oil changes keep hydraulic cylinders in top shape. This reduces repairs and saves time.

Machines That Use Hydraulic Cylinders

Many powerful machines depend on hydraulic cylinders to work properly. Here are some examples:

- Excavators – These powerful digging machines grip through the soil and heave up rocks using hydraulic cylinders. The cylinders thrust the arm and bucket forward which makes deep digging swift and effortless.

- Cranes – Cranes use hydraulic cylinders to lift and lower heavy loads. Whether at construction sites or shipyards, hydraulic power allows cranes to handle massive weights safely.

- Bulldozers – Hydraulic cylinders let bulldozers push soil, rocks, and debris. They control the blade’s angle and depth, helping shape the land as needed.

- Dump Trucks – The large container at the back of a dump truck tips upward using hydraulic cylinders. This allows materials like sand or gravel to slide out easily.

- Tractors – Farm tractors use hydraulic cylinders to lift ploughs, move hay bales, and pull heavy equipment. These cylinders make farm work much easier.

- Garbage Trucks – Hydraulic cylinders power the lifting arms that pick up bins and dump trash inside the truck. They also compact waste to make room for more.

Each of these machines relies on hydraulic cylinders to do heavy-duty work quickly and efficiently.

Choosing the Best Hydraulic Cylinder

Picking the right hydraulic cylinder singapore helps machines work better and last longer. Here’s what to think about:

1. How Much Weight It Lifts

The cylinder must handle the heaviest load it will lift or push. The right size stops early damage.

2. How Far It Moves

The stroke length tells how far the cylinder extends and retracts. The right length makes sure the machine moves properly.

3. Size of the Cylinder

A bigger cylinder makes more power. Heavy-duty machines need wider cylinders to work smoothly.

4. Pressure Strength

Machines work at different pressure levels. A well-matched cylinder keeps machines running without damage.

5. Working Conditions

Heat, cold, dust, and water can hurt cylinders. Strong materials protect them from bad weather and rough use.

By thinking about these things, businesses can pick the best hydraulic cylinder for their machines and keep them running well.

Hydraulic Cylinders in Singapore

Industries in Singapore use hydraulic cylinders for many jobs. Builders, farmers, and transport companies rely on them to make work easier. As machines get stronger, businesses need the best hydraulic cylinders singapore to stay ahead.

How to Take Care of Hydraulic Cylinders

Hydraulic cylinders work best when treated well. Good care stops breakdowns and helps them last longer. Here’s how to keep them working:

1. Check for Damage

Look for cracks, rust, or leaks. Fixing small problems early stops big, costly repairs.

2. Use Clean Oil

Dirty oil slows machines down and causes damage. Change hydraulic fluid often and use clean filters.

3. Lubricate Moving Parts

Friction wears out parts fast. Add lubricant to keep cylinders working smoothly.

4. Replace Seals

Seals stop leaks and hold pressure. If they wear out, cylinders lose power. Checking and replacing them keeps machines strong.

5. Store Properly

When not in use, keep hydraulic cylinders clean and dry. Dirt and moisture cause rust and wear. Storing them safely helps them last longer.

Conclusion

Hydraulic cylinders fuel big machines with power, speed and protection. They hoist, push and balance massive loads with ease in farming, mining and construction. These tough parts handle crushing pressure while moving with smooth, precise motion which makes them reliable tools for many industries. Choosing the right hydraulic cylinder and giving it regular care keeps machines strong for years. High-quality cylinders slash downtime, cut repairs, and boost efficiency. From diggers to garbage trucks, these mighty tools shape the world around us. Knowing their value helps businesses pick the best equipment, ensuring machines work safely and efficiently for a long time.