When it comes to industrial packaging, things move fast so protecting jobs is the priority. This is where the strapping bands of heavy-duty industrial strapping offer themselves and it is a quality alternative for keeping different items of cargo in unity during their transportation. A broad range of choices include polyester and metal strap bands which are a preferred option compared to others. Knowing the fundamentals of each of them, in addition to comprehending their applications and pros, is mandatory for companies concerning the appropriate packaging para them.

Polyester Strapping Bands: Strength and flexibility

Polyester tapes otherwise referred to as PET (polyethylene terephthalate) straps are renowned for their superior strength and versatility in the industry. Made of polyester fibers, those bands provide an impressive tensile strength ability, hence they are good for mattering heavy loads or offering a stabilization advantage.

Key Properties of Polyester Strapping Bands for Industrial Packaging

Polyester strapping bands boast several properties that make them highly desirable for industrial packaging:

High Tensile Strength: Through the high tensile strength of PET belts, the belt will accommodate any heavy loads and remain dependable.

Weather Resistance: To deal with moisture, UV rays, or extreme heat, polyester straps are resistant and maintain their lasting quality even when the environmental conditions are very hard to deal with.

Flexibility: Despite their strength, Alternatives to Polyester Straps (APET straps) are pliable (while not breaking) providing handling and application simplicity.

Safety: Polyester wear and environmental devastation are less likely to be the case than with nylon straps that can corrode during use, therefore, the safety level at the workplace is higher.

Applications of Polyester Strapping Bands Across Industries

The versatility of polyester strapping bands renders them suitable for a wide range of applications across various industries:

Transportation and Shipping: Strips of PET, normally used as shipping straps, are a way to fasten well-loaded pallets making sure they are safely delivered to the destination.

Construction: In the construction sector polytype straps are used to tie and bundle building components, such as lumber, and metal rods.

Manufacturing: Companies engaged in manufacturing are busy with packaging their products, keeping them secured, and facilitating the flow of logistic operations. These packages use PET straps.3. Advantages

Advantages of Polyester Strapping Bands Over Alternative Materials

Cost-Effectiveness: High-quality, cost-effective PET straps are the ideal choice for packaging applications including strapping bags and containers due to their superior performance and affordable costs.

Environmental Sustainability: PET straps are recyclable, thus contributing to greener packaging as a consequence.

User-Friendly: Easily handled through the straps and applied, this kind of polyester strap simplifies the packaging processes and thereby contributes to cutting down either labor costs or improving efficiency.

Getting the Foundational Polyester Strapping Tubing

When selecting polyester strapping bands for your packaging requirements, consider the following factors:

Width and Thickness: Select webbing with an adequate width and thickness to accommodate more weight and greater dimensions of the stuff.

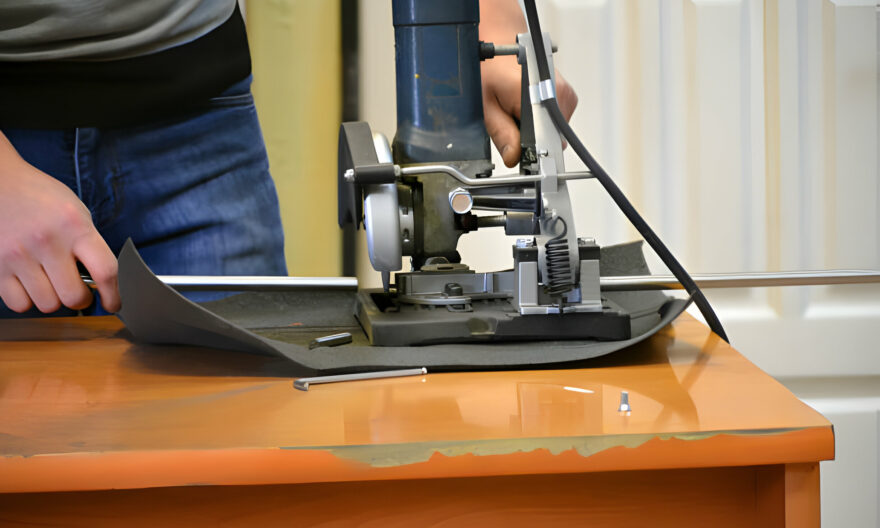

Tensioning Tools: Procure adequate tensioning tools made of good quality which will ensure that the movement of straps will be of the required tension and will provide for proper sealing.

Supplier Reputation: When looking for source material for your PET straps, it is advisable to choose from suppliers that are known for their quality workmanship and great attention to service.

Metal Strapping Bands: The last two important issues when discussing fashion for sustainability are durability and security.

Unique Properties of Metal Strapping Bands for Industrial Use

Metal strapping bands, typically made of steel, possess distinct properties that set them apart from other strapping materials:

Extreme Strength: Conversely, steel strapping bands present an unprecedented resistance to tensions and may be able to bind exorbitant heavyweights, and endure handling harshly and infrequently.

Corrosion Resistance: Wired or rigid steel straps are corrosion resistant and can be used in corrosive environments while Galvanized or stainless straps are suitable applications for aggressive environments.

High Retention Force: Metal straps will stay tight over far distances making sure that you can segment the product properly during the process of carrying it.

Temperature Resistance: Steel belts, by their capability to retain strength and integrity without any change at any temperature, can be made applicable for a variety of environmental conditions.

Common Applications of Metal Strapping Bands in Industrial Settings

Metal strapping bands find extensive use in industries where robust packaging solutions are essential:

Heavy Machinery: Metal tracks are used as mounts to carry heavy machinery or any equipment during transportation and are secure for safe storage.

Timber and Lumber: In the papermaking industry, steel straps are used to tighten and lock the timber and lumber products.

Metal Fabrication: Steel straps are one significant player in bundling metal elements and fabricated parts, thus basically preventing shipping damage.

Selection of the Right Metal Strapping Bands

When choosing metal strapping bands for your packaging needs, consider the following factors:

Material and Finish: Choose steel straps that possess the adequate composition and finish (for example, if Galvanized or Stainless-steel fits your application) based on your use conditions.

Edge Protection: Put edged protectors to protect the goods from harm. Moreover, straps are dangerous and can hurt the metal strap.

Tensioning Equipment: Invest in high-quality tools and equipment built especially for welding operations using metal bands to make sure the proper degree of welding is achieved.

Conclusion

Polyester straps provide multiple functions, being inexpensive and simple to handle, and therefore this particular strap type is the one that is most frequently used in many industrial applications. On the contrary, metal straps can outcompete themselves with their unmatched strength, durability, and security, tremendously helping with heavy-duty packing activities. Through a realization of the peculiarities, uses and merits of each kind of strapping band, a company is in a position to make informed decisions on how cargo is to be packed safely and securely and, thus, end up with the theoretical advantages that can consequently lead to customers’ satisfaction at the practical level.