Efficiency is critical in the ever-increasing speed of manufacturing. Automation is one great method to increase efficiency. One such modern piece of equipment is an automatic palletizer machine that allows one to automate the processes, avoids manual labor, and saves time.

But just like other machines, it needs to be maintained from time to time so that it can work efficiently. Automatic palletizer machines in Malaysia due to its humid climate and industrial demands, must be maintained properly.

Here are some tips on maintaining your palletizer to keep it running as well as new.

How Your Automatic Palletizer Machine Works?

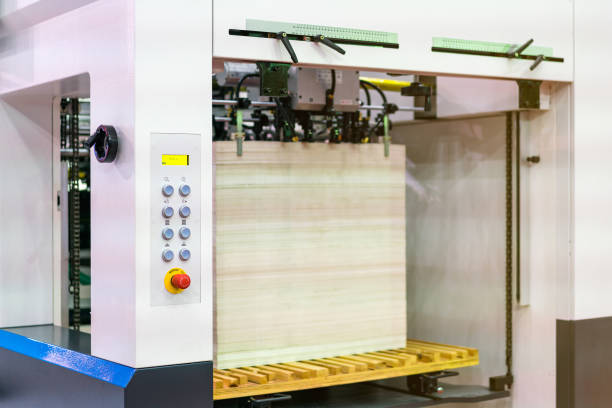

A palletizer is an automatic pallet, and these machines operate by stacking products on top of a pallet; it requires minimum human intervention. Different kinds of factories use this – everything from the food and beverage industry. Now, the device can speedily and precisely stack products ready for shipping or storage, thus increasing productivity. Just like a car, regular maintenance is needed for it to work properly.

Why Regular Service is So Important?

You must prevent unexpected breakdowns of the palletizer machine by conducting routine maintenance. It helps to maximize the efficiency of this machine. Overslaught on maintenance can result in expensive repairs and downtime. This type of maintenance is good for Malaysia, which has a more humid tropical environment, to prevent corrosion and other weather-related issues.

Daily Maintenance Tips:

Inspect for Visible Damage

Inspect daily for any wear or damage to be visible. Check for cracks, rust, or any other discoloration. They can catch and fix small issues before they become big problems.

Clean the Machine

This can cause dust and dirt to pile up, which leads to performance issues. Dust the machine every morning to clean it. Feel free to use a soft cloth and avoid strong chemicals or abrasives.

Lubricate Moving Parts

For smooth operation, lubrication is essential. Ensure parts have adequate lubrication every day to avoid friction and wear.

Weekly Maintenance Tips:

Check for Loose Bolts and Screws

Over time, bolts and screws can become loose due to vibration. Weekly: Inspect for loose bolts and screws. This will stop them from being a problem.

Check Electrical Connections

Examine your electrical connections for wear or damage. Malfunctioning may happen due to loose or damaged-ended connections. Check all of the wall and product connections.

Test Safety Features

Unfortunately, accidents can happen even with a good tow rig, but safety features are necessary to avoid this.

Monthly Maintenance Tips:

Inspect Belts and Chains

Belts and chains tend for you to wear gradually. Monthly check for signs of wear or damage. When something happens to good parts, fix them before they completely fall apart!

Check Hydraulic Systems

The operation requires hydraulic systems. Ensure that hydraulic fluid is topped off and leak-free. Mend or top it up as required to make sure that the system works well.

Test the Control System

Your control system is like the brains of your machinery. Check it monthly to make certain that it is functioning properly. Install appropriate updates to minimize the risk of glitches.

Seasonal Maintenance Tips:

Prepare for Humidity

Another reality is the harsh climate of Malaysia, which can be devastating to its machinery. Inspect anything that could be problematic due to humidity before the wet season. Use anti-rust measures to keep out corrosion.

Inspect Cooling Systems

They are responsible for making sure your system does not overheat. Check them before the summer months. Make sure the system works as it should, and clean or replace any filters.

General Maintenance Tips:

Depends on the Manufacturer

Manufacturer relationships will also be an essential phase in the bulletin upkeep guidelines. They know their machines and provide clear recommendations to achieve the best results.

Keep a Maintenance Log

A maintenance log is used to record the date and time. Certain procedures are followed before addressing a problem. Above all, measures are performed while fixing equipment. The system is used to report faults or describe symptoms. Remember all examinations, repair works, and replacements. This is useful for planning future maintenance and locating issues that repeat.

Train Your Staff

Staff who are trained can do simple facility maintenance work. Train them occasionally in order for them to understand what machine it is and its maintenance needs. This means that the machine will need less energy to function and produce a burning chamber, so it translates into a longer lifespan.

Troubleshooting Common Issues:

Machine Stops Working

If you suddenly stop working, first check the power supply. The machine is connected and not a tripped circuit breaker. If the power supply is correct, look for error messages on the Control panel. If required, refer to the instructions or contact a professional.

Products are Not Stacking

If the products are not stacking correctly, then check the alignment regarding pallet and product. Make sure the pallet is located in an appropriate position and that your product picking up accurately. Adjust settings if necessary.

Unusual Noises

They can signify a problem like no other noise. Look for any parts lying loose or debris within the machine. Once you have lubed the moving parts and made sure nothing is wiggly,

Benefits of Routine Peace of Mind:

Maintenance is not just required to prolong the life of your car but has several benefits associated with it. This also helps extend the machine’s life and decrease expensive replacements. It makes the machine work effectively without wasting money and time. It also improves safety as it eliminates any risk of accidents or injuries.

Conclusion:

Your automatic palletizer machine is something you need to take care of for it to last long and work as efficiently as possible. Inspection of the cable, cleaning, and lubrication are important. Follow the service manual for your car and keep track as well. Educate members of your staff on general maintenance procedures.