Proper selection of the right equipment is important because of safety, work performance, and project success in regards to working at heights. One of the most common dialogs is when you choose an aerial work platform (AWP) or traditional equipment for your project. Both have their benefits and limitations, so you should examine the differences between them before making a final choice. In this post, we will look into what distinguishes them as aerial work platforms from conventional elevators and how to determine the most appropriate one to use in your next project.

Aerial Work Platforms (AWPs)

The AWP, often called a boom lift, is one of the most versatile pieces of equipment for providing temporary access to high work sites. The use of these platforms stretches far beyond construction and maintenance into many other industrial applications.

Key Features of Aerial Work Platforms

- Mobility: The AWP allows easy access to various areas for workers.

- Reach: The reach for AWPs, indirectly for boom lifts, can reach quite considerable heights—up to 185 feet, sometimes.

- Adjustable Positioning: The platform can be adjusted to different angles and heights suitable for complex works in hard-to-reach areas.

Types of Aerial Work Platforms

There are many kinds of aerial work platforms, and each one serves specific tasks and environments.

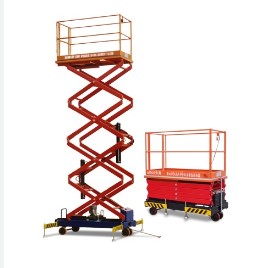

1. Scissor Lifts

- Overview: Scissor lifts have a crisscrossing support system that enables them to raise a platform vertically.

- Applications: Best designs for straight-up elevation tasks indoors, such as maintenance, electrical work, window cleaning, etc.

- Height: The average scissor lift will go to about 50 ft. high. Model types may vary.

2. Boom Lifts

- Overview: Boom lifts are also referred to as cherry pickers. They are more flexible compared to scissor lifts. They have extendable arms that rotate and extend vertically and horizontally.

- Applications: They find applications in jobs that require access to high areas and those that are awkwardly positioned. Typical applications include tree trimming, painting, and construction work on tall buildings.

- Height: They may achieve heights of up to 185 feet high.

3. Vertical Mast Lifts

- Overview: These lifts come compactly made for working in tight spaces where other lifts wouldn’t be able to fit.

- Applications: Excellent for tiny jobs indoors, such as setting ceilings, painting, or even changing light bulbs.

Understanding Traditional Lifts

Traditional lifts refer to more basic systems of lifts that mostly operate manually, such as ladders, scaffolding, or mechanical jacks. Typically used in construction and industrial settings, these options are less versatile than an AWP.

Key Features of Traditional Lifts

- Simple Operation: Traditional lifts usually operate on a manual basis or through basic mechanical means.

- Cost-Effective: They are generally less expensive than AWPs.

- Limited Reach: Traditional lifts typically cannot reach the same heights as AWPs, limiting their use for high-elevation projects.

- Less Flexibility: Traditional lifts don’t offer the same level of maneuverability or positioning flexibility as AWPs.

Traditional Lifts: Pros and Cons

Moreover, to help you decide whether traditional lifts suit your project, it’s important to consider their advantages and disadvantages.

Pros:

- Cost Efficiency: Traditional lifts are more affordable, which is a key consideration for smaller projects.

- Availability: Scaffolding and ladders are commonly available, making them a convenient option for many tasks.

- Simplicity: Traditional lifts require minimal setup and training, which can save time in the initial stages of a project.

Cons:

- Limited Reach: Traditional lifts don’t offer the same height advantages as AWPs, which may hinder your ability to work at elevated levels.

- Manual Operation: Many traditional lifts rely on manual labor, which can be tiring and less efficient than powered AWPs.

- Safety Concerns: Traditional lifts pose more significant safety risks compared to AWPs. For example, ladders are prone to slipping, and scaffolding requires more setup and takedown effort.

When to Choose an Aerial Work Platform (AWP)

AWPs are ideal for projects that require access to difficult or high areas. Scenarios where AWPs, are beneficial include:

- High-Elevation Projects: For work on tall buildings, wind turbines, or large signs, AWPs provide the necessary height and stability.

- Outdoor Construction: AWPs excel on rough terrain, offering maneuverability for outdoor projects.

- Complex Access Needs: AWPs can reach tight spots and navigate around obstacles with both horizontal and vertical flexibility.

When to Choose a Traditional Lift

Traditional lifts are more suited for simpler, smaller projects. Consider traditional lifts in the following cases:

- Low-Cost Projects: For basic tasks that don’t require significant elevation, scaffolding or ladders are cost-effective options.

- Indoor Maintenance: For tasks like painting or repairs at lower heights, traditional lifts are convenient and affordable.

- Short-Term Projects: Quick, low-complexity jobs can often be completed more economically with traditional lifts.

Safety Considerations: AWPs vs. Traditional Lifts

Regardless of the type of lift you choose, safety should always be a top priority. Both AWPs and traditional lifts require adherence to specific safety protocols to ensure worker protection.

Safety Tips for AWPs:

- Safety: Inspect the AWP before using it to ensure that it is in good condition.

- Proper training: Ensure that all operators of any plant equipment are trained to operate it safely.

- Use harnesses: Use safety harnesses while working at heights and ensure that the harness is properly attached to the platform.

Safety Tips for Traditional Lifts:

- Firm Grounding: Ladders and scaffolds need to be firmly placed on level ground to avoid accidents.

- Secure Connections: While working with scaffolding, always make sure that the connections are secure before doing the actual work.

- Proper Use: Never overreach or overload conventional lifts, as this may cause them to tip and increase your risk of falling.

Conclusion: Choosing the Right Equipment for Your Project

While the choice between aerial work platforms and traditional lifts will depend on the scope and requirements of your project, an AWP is most likely your best option if your project involves high heights, complex access needs, or outdoor construction. Traditional lifts suit small, short-term, or low-cost projects that don’t require advanced elevation.